Baumüller will be presenting numerous new products at SPS. In hall 1, stand 560, Baumüller will be displaying clever motor concepts, intelligent drive functions and powerful control platforms on various stations. The connectivity and interoperability of components via OPC UA and cloud connectivity will be presented in the Industry 4.0 area.

Baumüller components extended to include IoT connectivity

Baumüller is extending its components to include further, extensive IoT functions. This makes it easy to network and control of machines and machine modules through to individual automation components. With the new IoT functions, data can be collected, preprocessed and output directly at other terminal devices or on the cloud. They make extensive and complex data analyses possible, in order to enable Industry 4.0 applications, such as predictive maintenance. At the same time, new business models, such as “x per use” can be achieved.

Individual parameterization for the analysis of data through to creation of their own dashboards by users can be undertaken directly on the component. The available MQTT module allows data to be read in from different clouds; regardless of the respective cloud provider. It also includes an OPC UA module, which ensures interoperability at machine level.

With Node-Red, the components have a graphic parameterizing interface (flow based), so that data can be analyzed, further processed and visualized directly at the machine.

Data from different manufacturers’ devices can be processed. Data from Baumüller products, for example, of a b maXX converter, can be output in parallel to the fieldbus via the internal protocol and thus via the service interface. Due to the enhanced functions, the connectivity of Baumüller devices, such as the b maXX PCC04, with other automation components can be established via OPC UA.

New generation of the b maXX 5300 module systems – higher security functions, greater flexibility

The b maXX 5000 converter family has convincingly high-performance power units, flexible expandability and an integrated communication concept. With the new edition of the b maXX 5300, Baumüller is revising its module systems and is making them even more powerful and flexible for customer use. Thanks to numerous hardware and software options, in future, customer and application requirements can be met with even more granular solutions. For example, the number of secure I/Os can be adjusted to the respective requirements of the application.

In addition, new security functions are integrated in the b maXX 5300, such as transfer of the secure position via FSoE to a high-level safety control. With this function, secure space monitoring and secure collaboration between several axes can be implemented, for example, in robotics applications.

Higher accuracy with regard to encoder resolutions is possible with the new devices. Thus, used with security technology with a single resolver, the device has a speed resolution of less than 1 rpm. This high position and speed accuracy is particularly important for highly dynamic applications, for example, for textile machines or handling systems.

A further advantage is the faster response time to events: For example, on triggering the STO security function, the controller is switched without torque with a delay of less than 1 ms.

In addition, the ETG standard for FSoE communication is implemented with the new generation of the module systems. This means that the b maXX converters can also be easily linked to higher-level safety controls of other manufacturers.

Intelligence in the drive

The intelligent converters of the Baumüller b maXX 5000 product family with integrated softdrivePLC enable data analyses directly in the drive. In this way, logic operations cannot only be parameterized, but also be programmed. An example: If the control circuits vibrate due to resonant frequencies, this vibration can be minimized with the help of a more dynamic setting and productivity is increased.

Vibrations in the mechanics can also be filtered out with the intelligent b maXX converters.

Numerous controller functions are integrated in the b maXX 5000 series, to make the system even more efficient and intelligent. Functions such as transmission protection, adaptation of the controller parameters, error reactions or monitoring the thermal pump load via a temperature model ensure lower service costs, shorter standstill times and lower system costs.

Numerous features: The new servo pump software version V2+

The adaptive pressure precontrol is a significant improvement of the software modules of the control function in the new servo pump software version V2+. The intelligent control algorithm adjusts adaptively to different pressure rise rates; this means that the parameterization only has to be set once and is then automatically regulated. The software enables an overshoot-free pressure jump in minimum time, thus ensuring an optimized process sequence. Since the corresponding parameters adjust automatically with a standard cycle of 125 μs during the production process, the adaptive control eliminates or greatly reduces pressure overshoots. The required pressure value therefore sets in fully automatically with controlled transition.

The experts at Baumüller have enhanced the new software version V2+ of the servo pump to include several protection functions, so that wear of highly loaded parts of the servo pump does not influence the quality of the end products and also the load on the machine components is reduced. For example, by default, the pump load is monitored within highly loaded pressure maintenance mode. If the temperature model indicates a thermal overload, the bypass valves open automatically to remove the overheated oil. The servo pump is cooled until it has returned to normal temperature. A further positive aspect of the monitoring concerns the leakage characteristic. In the new version, this can be additionally recorded and compared with reference data. This makes diagnosis easier and wear or necessary replacement of the valves and seals can be detected faster.

New power supply units for high performances

The converter series b maXX 5000 includes feed-in and regenerative units as well as drive units, which can be quickly and easily combined by an integrated drive connect system. This allows the machine builder to benefit from low installation costs and short commissioning and service times. The converters are available for air, water and oil cooling methods and, thanks to their high power density, they require a very small installation space. The power supply units have now been expanded to include peak output of up to 300 kW. This is ideal, for example, for dynamic movements, such as opening and closing the injection mold or for the forming process in servopresses, where high peak power outputs are required at short notice. With a peak current of 420 A, the large axes are ideally suited for maximum dynamic performance.

Engineering 4.0: Faster time-to-market with the new ProSimulation software

Virtual configuration and testing of automation systems: The newly developed ProSimulation software provides customers with a platform for getting started with the world of simulation quickly. The new tool simplifies the virtual design, optimization and commissioning of machines and systems.

Depending on customers’ levels of experience, they can quickly set up their own simulations and applications using the basic library or import existing software models due to to open interfaces. The advantages of ProSimulation include time and cost savings in the development and commissioning of new machines and systems as well as the optimization of existing machines. In addition, the company can build up urgently needed simulation expertise for the future, thus building competence in the areas of Industry 4.0 and digital twins. ProSimulation expands the functional range of the ProDrive software, which allows quick and easy commissioning, parameterization and operation of the b maXX converter family.

ProSimulation permits virtual parameterization to optimize machine behavior. Real added value for the industry, because due to ever shorter development cycles in mechanical engineering, innovations can be tested within the shortest possible time, including offline. This means forward-looking positioning for optimum development.

Greater performance: compact water-cooled servomotors

Baumüller is expanding its range of servomotors to include the water-cooled models in sizes 45 and 56. With their space-saving installation and very high power density, the small models really come into their own with their water-cooling benefits. This enables motors installed in very tight spaces to be used at high power ratings. For the machine manufacturer, this means optimal mechanical properties, lower costs and better efficiency.

In addition to the cost savings, the small water-cooled models also offer further advantages when it comes to installation space: The outer dimensions of the housing family are the same as an uncooled version; however, it offers significantly more performance. It therefore combines the advantage of maximum cooling with minimum motor dimensions. Another advantage offered by heat dissipation through the cooling medium of water is that the motors can be placed next to one another even when installed in tight spaces without causing each other to heat up.

Baumüller completes its series with water cooling of size 45 and 56 servomotors, and is thus the only manufacturer to also offer smaller sized servomotors with all cooling methods.

Global life cycle management

In addition to the development and manufacture of automation components, Baumüller as a group of companies provides numerous services for mechanical and plant engineering and for machine operators. From project planning, design and engineering through assembly and commissioning, service to maintenance, retrofitting and relocation, Baumüller offers support over the entire life cycle of machines and systems. Within its smart services, Baumüller offers consultation and services for remote maintenance, diagnostics and networked production. With its subsidiaries Baumüller Reparaturwerk and Baumüller Anlagen-Systemtechnik, Baumüller also contributes its long-term experience in service, monitoring and optimizing automation & drive systems.

With more than 40 branches worldwide, Baumüller is a reliable service partner with global network and decades of local experience, and is therefore extremely familiar with the respective national and regional circumstances.

#PAuto @be_in_motion

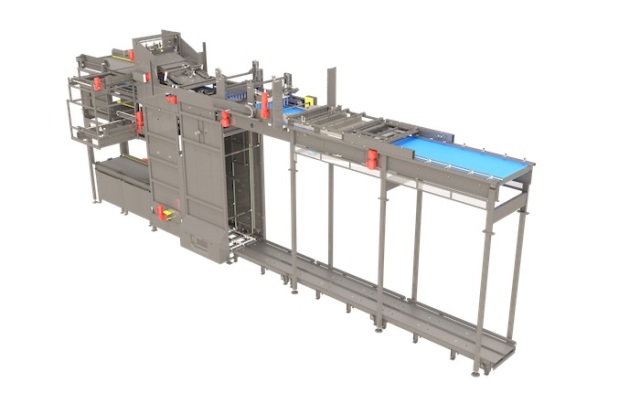

The Busse SJI Viper™ High Speed Bulk Palletizer and Alpha Turbo™ High Speed Depalletizer are paired with Emerson’s machine health monitoring to give customers a solution for greater overall equipment effectiveness (OEE) by monitoring, in real-time, critical motion and pneumatic system parameters including air flow, pressure, vacuum, mechanical actuation speeds and motor vibration. System analytics and health information is processed at the edge via a local data historian with both local display or remote monitoring on a tablet or smartphone giving operators an easily accessible tool to monitor health.

The Busse SJI Viper™ High Speed Bulk Palletizer and Alpha Turbo™ High Speed Depalletizer are paired with Emerson’s machine health monitoring to give customers a solution for greater overall equipment effectiveness (OEE) by monitoring, in real-time, critical motion and pneumatic system parameters including air flow, pressure, vacuum, mechanical actuation speeds and motor vibration. System analytics and health information is processed at the edge via a local data historian with both local display or remote monitoring on a tablet or smartphone giving operators an easily accessible tool to monitor health.

Emerson

Emerson The Rogowski coils range to measure current up to 300,000 A AC with accuracy class 0.5 are being launched by LEM at SPS. The ARU range achieves IEC 61869-10 class 0.5 without the need for additional components such as resistors or potentiometers to calibrate the coil, which can drift over time. The range benefits from ‘Perfect Loop’ technology, a unique patented coil clasp that eliminates the inaccuracy caused by sensitivity to the position of the conductor inside the loop. This technology provides an innovative, robust and fast ‘Twist and Click’ closure.

The Rogowski coils range to measure current up to 300,000 A AC with accuracy class 0.5 are being launched by LEM at SPS. The ARU range achieves IEC 61869-10 class 0.5 without the need for additional components such as resistors or potentiometers to calibrate the coil, which can drift over time. The range benefits from ‘Perfect Loop’ technology, a unique patented coil clasp that eliminates the inaccuracy caused by sensitivity to the position of the conductor inside the loop. This technology provides an innovative, robust and fast ‘Twist and Click’ closure. Packaged as SO16 surface-mount devices with a height of just 6 mm, the sensors can be mounted directly onto a printed circuit board in the same process as other board-level components. This helps to reduce manufacturing costs and decrease the overall footprint, vital for space-constrained applications. As a result, HMSR sensors can be readily built into small form-factor intelligent power modules (IPMs).

Packaged as SO16 surface-mount devices with a height of just 6 mm, the sensors can be mounted directly onto a printed circuit board in the same process as other board-level components. This helps to reduce manufacturing costs and decrease the overall footprint, vital for space-constrained applications. As a result, HMSR sensors can be readily built into small form-factor intelligent power modules (IPMs).

iCOMOX is very fast to deploy. It comes ready to use with embedded software and on-board time-domain, as well as FFT analytics for condition-based maintenance (CBM) of industrial assets such as machinery, production lines and structures. CE and FCC certified, iCOMOX is housed in a compact and rugged IP66-rated enclosure. A selection of adapters is provided to facilitate attachment to various types of equipment.

iCOMOX is very fast to deploy. It comes ready to use with embedded software and on-board time-domain, as well as FFT analytics for condition-based maintenance (CBM) of industrial assets such as machinery, production lines and structures. CE and FCC certified, iCOMOX is housed in a compact and rugged IP66-rated enclosure. A selection of adapters is provided to facilitate attachment to various types of equipment.

With smart gateways and mobile enterprise solutions, Softing Industrial Data Networks presents itself at the SPS 2019 trade show in Nuremberg as a partner for the process industry on its way to digitalization.

With smart gateways and mobile enterprise solutions, Softing Industrial Data Networks presents itself at the SPS 2019 trade show in Nuremberg as a partner for the process industry on its way to digitalization.

“Fast Forward to the Future” is the trade fair motto of the company during SPS (Hall 3, stand 250). For the second generation of servo motors, the control arm is at full throttle. The high power density with greater torque per engine size opens up new ways to construct machinery as a smaller overall size is often sufficient to handle the AKM2G. Above all, compact applications with a high functional density benifit most from this feature, for example, in the design of collaborative robot kinematics and automated guided vehicles (AGV).

“Fast Forward to the Future” is the trade fair motto of the company during SPS (Hall 3, stand 250). For the second generation of servo motors, the control arm is at full throttle. The high power density with greater torque per engine size opens up new ways to construct machinery as a smaller overall size is often sufficient to handle the AKM2G. Above all, compact applications with a high functional density benifit most from this feature, for example, in the design of collaborative robot kinematics and automated guided vehicles (AGV). This new portfolio will encompass a range of innovative Industrial Ethernet technologies for building robust, scalable Ethernet connectivity solutions that advance the state-of-the-art in edge connectivity, data integration, synchronization, and system interoperability. Designed both for today’s industrial networks and tomorrow’s TSN-based systems, this portfolio will provide the flexibility, scalability and speeds to support virtually any topology and network architecture in the factory.

This new portfolio will encompass a range of innovative Industrial Ethernet technologies for building robust, scalable Ethernet connectivity solutions that advance the state-of-the-art in edge connectivity, data integration, synchronization, and system interoperability. Designed both for today’s industrial networks and tomorrow’s TSN-based systems, this portfolio will provide the flexibility, scalability and speeds to support virtually any topology and network architecture in the factory. To help enable new digital transformation strategies, this industrial networking solution combines Emerson’s expertise in industrial automation and applications with Cisco’s innovations in networking, cybersecurity and IT infrastructure. Driven by the demand for greater productivity, lower maintenance costs and improved worker safety, industrial manufacturers are accelerating investment in robust IoT sensor networks combined with scalable operational analytics tools to improve organisational collaboration and decision-making. In these environments, network performance and security are critical for success.

To help enable new digital transformation strategies, this industrial networking solution combines Emerson’s expertise in industrial automation and applications with Cisco’s innovations in networking, cybersecurity and IT infrastructure. Driven by the demand for greater productivity, lower maintenance costs and improved worker safety, industrial manufacturers are accelerating investment in robust IoT sensor networks combined with scalable operational analytics tools to improve organisational collaboration and decision-making. In these environments, network performance and security are critical for success.

Bosch has been presenting these awards every two years to honor supplier excellence since 1987. Suppliers are selected for outstanding performance in the manufacture and supply of products or services – notably for partnership in addressing concerns around quality, costs, innovation and logistics. This year’s award ceremony, whose theme was “Transforming Together. Staying Ahead,” was held in Blaichach, Germany.

Bosch has been presenting these awards every two years to honor supplier excellence since 1987. Suppliers are selected for outstanding performance in the manufacture and supply of products or services – notably for partnership in addressing concerns around quality, costs, innovation and logistics. This year’s award ceremony, whose theme was “Transforming Together. Staying Ahead,” was held in Blaichach, Germany.

Report & Links

Report & Links

Emerson Exchange Daily

Emerson Exchange Daily

Honeywell User Group Meeting

Honeywell User Group Meeting

Hannover Fair on twitter.

Hannover Fair on twitter.